|

| |

|

| |

Backscattered Electron Imaging

Do

You Know Everything We Do?

MEi President

on Careers CD

MEi Briefs

The

Lighter Side

Ann Landers: On Product Safety!

The "What Is It?" Contest |

What

It Is and What It Can Do For You

While most of us

have been exposed to or are familiar with the scanning electron microscope

(SEM) as a powerful tool for failure analysis and contamination identification,

you may not be familiar with the use of the SEM in the back-scatter

image analysis mode, commonly referred to as BEi or simply back-scatter. While most of us

have been exposed to or are familiar with the scanning electron microscope

(SEM) as a powerful tool for failure analysis and contamination identification,

you may not be familiar with the use of the SEM in the back-scatter

image analysis mode, commonly referred to as BEi or simply back-scatter.

What is it?

In normal mode,

the SEM creates an image by gathering the low energy secondary electrons

which are ejected from the atoms within the sample. In the back-scatter

mode, high energy electrons from the incident beam "bounce"

off the atoms of the sample and are gathered. The intensity of the

image is related to how many electrons bounce off or are scattered

back, hence the term back-scattered. The heavier elements, such as

tungsten and molybdenum, have larger nuclei and thus have a higher

probability of creating back-scattered electrons. The energy of back-scattered

electrons does not vary with the element, only with the operating

voltage of the SEM. In normal mode,

the SEM creates an image by gathering the low energy secondary electrons

which are ejected from the atoms within the sample. In the back-scatter

mode, high energy electrons from the incident beam "bounce"

off the atoms of the sample and are gathered. The intensity of the

image is related to how many electrons bounce off or are scattered

back, hence the term back-scattered. The heavier elements, such as

tungsten and molybdenum, have larger nuclei and thus have a higher

probability of creating back-scattered electrons. The energy of back-scattered

electrons does not vary with the element, only with the operating

voltage of the SEM.

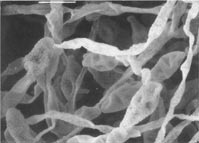

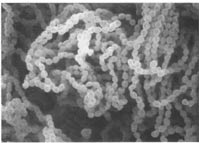

In the conventional

SEM photo (left) the metal shaving all look alike. However, the contrast

difference in the backscatter image (right) reveals the shavings are

a misture of three different metals.

45X 45X 45X

45X

What does this really mean?

The information

provided by each mode is dramatically different. In the normal secondary

electron mode, the contrast observed is due primarily to topography,

and is generally rather low. In the back-scatter mode, the contrast

observed is due to differences in atomic number. The high atomic number

elements (e.g. molybdenum, tungsten and lead) appear bright in contrast

to the low atomic number elements (e.g. aluminum, silicon and titanium). The information

provided by each mode is dramatically different. In the normal secondary

electron mode, the contrast observed is due primarily to topography,

and is generally rather low. In the back-scatter mode, the contrast

observed is due to differences in atomic number. The high atomic number

elements (e.g. molybdenum, tungsten and lead) appear bright in contrast

to the low atomic number elements (e.g. aluminum, silicon and titanium).

Uses of BEi

Back-scatter allows

for quick and easy identification of phases with different elemental

compositions. What does this mean in a practical sense? In a tool

steel, the tungsten and molybdenum carbides appear brighter than chromium

carbides, permitting quick differentiation. In leaded bronze, a segregation

of the lead phase within the structure stands out against a dark background.

Heavy metal platings appear white on a fracture surface, providing

insight into whether a crack occurred in manufacturing prior to plating,

or during usage. Back-scatter allows

for quick and easy identification of phases with different elemental

compositions. What does this mean in a practical sense? In a tool

steel, the tungsten and molybdenum carbides appear brighter than chromium

carbides, permitting quick differentiation. In leaded bronze, a segregation

of the lead phase within the structure stands out against a dark background.

Heavy metal platings appear white on a fracture surface, providing

insight into whether a crack occurred in manufacturing prior to plating,

or during usage.

The photographs show a group of metal shavings. In the conventional

SEM photograph, all the shavings appear the same shade of gray. However,

in back-scatter imaging, the shavings appear as bright, gray, and

dark. EDS analysis confirms the shavings to be a mixture of aluminum

(dark), steel (gray) and silver plating (bright).

The photographs show a group of metal shavings. In the conventional

SEM photograph, all the shavings appear the same shade of gray. However,

in back-scatter imaging, the shavings appear as bright, gray, and

dark. EDS analysis confirms the shavings to be a mixture of aluminum

(dark), steel (gray) and silver plating (bright).

Summary

Back-scattered

electron imaging is a good complement to conventional secondary electron

imaging on the scanning electron microscope, and is a powerful tool

for certain applications. If you have a materials processing problem

that you think back-scatter imaging would be the ideal tool to help

you resolve, just give us a call to discuss the possibilities. Back-scattered

electron imaging is a good complement to conventional secondary electron

imaging on the scanning electron microscope, and is a powerful tool

for certain applications. If you have a materials processing problem

that you think back-scatter imaging would be the ideal tool to help

you resolve, just give us a call to discuss the possibilities.

While

many of our customers have worked with us on several projects through

the years, we are sure that some of our customers may not be familiar

with the full range of services we offer. Hopefully, this list will

give you a better idea of the range of services we offer. As always,

we have an open invitation for any of our customers to come to Virgil

to see how we do things. While

many of our customers have worked with us on several projects through

the years, we are sure that some of our customers may not be familiar

with the full range of services we offer. Hopefully, this list will

give you a better idea of the range of services we offer. As always,

we have an open invitation for any of our customers to come to Virgil

to see how we do things.

Our Services |

Failure

Analysis

• Wear

• Fatigue

• Corrosion

• Hydrogen Embrittlement

• Ductile or Brittle Overload

• Improper Design or Misuse

• Material & Processing Defects Contamination

Identification

• Residues and Surface Films

• Corrosion Products

• Wear Debris

• Particles

• Plating & Joining Adhesion Problems

• Electronics, Medical Contaminants

Complete Metallurgical Laboratory

• Scanning Electron Microscopy

• EDS Chemical Analysis

• Metallography and Microscopy

• Microhardness and Hardness |

Analysis

of Processing Problems

• Welding, Brazing and Soldering

• Stamping and Metal Forming

• Casting and Forging

• Plating and Coating

• Heat Treating

• Powder Metal

Engineering Services

• Design Support

• Materials Selection

• Problem Analysis & Corrective Action

• Materials and Process R&D

We Also Provide

• On Site Investigations

• Specialized Product Testing

• Expertise in Electronics, Ceramics & Polymers

• Product Liability Investigations

• Expert Testimony |

And Tensile strength, chemical composition, FTIR, physical properties

and

Tensile strength, chemical composition, FTIR, physical properties

and

corrosion testing are available though our network of associated laboratories.

Last

spring, video production specialist Elizabeth Hogan of Ruder-Finn

in New York City spent a day at the MEi facility in Virgil, Illinois

interviewing Bill Durako about Careers in Metallurgy and Materials

Engineering. The interview is part of a project called the Career

Resource Center (CRC) being developed by TMS-AIME for the materials

engineering profession. Last

spring, video production specialist Elizabeth Hogan of Ruder-Finn

in New York City spent a day at the MEi facility in Virgil, Illinois

interviewing Bill Durako about Careers in Metallurgy and Materials

Engineering. The interview is part of a project called the Career

Resource Center (CRC) being developed by TMS-AIME for the materials

engineering profession.

The

CRC project is funded by the Arthur P. Sloan Foundation. It features

interviews and comments with professionals in a variety of technical

professions, including materials, mechanical, electrical, chemical

and civil engineering, as well as physics, chemistry, geology and

mathematics. The

CRC project is funded by the Arthur P. Sloan Foundation. It features

interviews and comments with professionals in a variety of technical

professions, including materials, mechanical, electrical, chemical

and civil engineering, as well as physics, chemistry, geology and

mathematics.

The

project is targeted primarily at high school students. The goal of

the project is 'to build public awareness of Science and Engineering

fields and to provide students with comprehensive information with

which to make informed academic and career decisions.' The

project is targeted primarily at high school students. The goal of

the project is 'to build public awareness of Science and Engineering

fields and to provide students with comprehensive information with

which to make informed academic and career decisions.'

TMS of AIME was selected to develop the Materials Science and Engineering

portions of the CRC, and hopes to use the project to demonstrate the

many opportunities available to students studying materials engineering.

The completed project

will consist of an interactive CD ROM to be distributed to high schools

and universities, a World Wide Web site that will offer a wealth of

academic and statistical information, and an accompanying booklet

for student distribution listing key facts on accredited university

science and engineering programs, and course requirements. The high

tech interactive presentation is full of examples aimed at being entertaining

as well as informative. The multimedia format will feature Quicktime

video clips with practicing engineers. Bill Durako is one of these

so called 'Featured Engineers'. The completed project

will consist of an interactive CD ROM to be distributed to high schools

and universities, a World Wide Web site that will offer a wealth of

academic and statistical information, and an accompanying booklet

for student distribution listing key facts on accredited university

science and engineering programs, and course requirements. The high

tech interactive presentation is full of examples aimed at being entertaining

as well as informative. The multimedia format will feature Quicktime

video clips with practicing engineers. Bill Durako is one of these

so called 'Featured Engineers'.

The

interview covered everything from a typical day and the most enjoyable

aspects of the job, to how he decided to pursue the career path and

what advice he would give to others interested in this field. Both

the CD-ROM and World Wide Web site feature "Live from the Home

Offices in Virgil, IL: Bill's Top Ten List of Things to Assist You

in Your Engineering Career." The

interview covered everything from a typical day and the most enjoyable

aspects of the job, to how he decided to pursue the career path and

what advice he would give to others interested in this field. Both

the CD-ROM and World Wide Web site feature "Live from the Home

Offices in Virgil, IL: Bill's Top Ten List of Things to Assist You

in Your Engineering Career."

The

CD-ROM is in the final stages of production and is scheduled to be

released this summer. The world wide web site has many of the features

completed, but is still under construction. You can check on the progress

at www.crc4mse.org. The

CD-ROM is in the final stages of production and is scheduled to be

released this summer. The world wide web site has many of the features

completed, but is still under construction. You can check on the progress

at www.crc4mse.org.

"I enjoyed being a part of this project. I know many high school

students struggle with what they want to do with their lives. It's

tough to make a decision without information. So many people either

have a misunderstanding of what engineers do, or are pushed into engineering

because they are good at math and science. Hopefully, the CRC CD-ROM

and web site will provide insight into what engineers and scientists

actually do, and help students with their career decisions."

"I enjoyed being a part of this project. I know many high school

students struggle with what they want to do with their lives. It's

tough to make a decision without information. So many people either

have a misunderstanding of what engineers do, or are pushed into engineering

because they are good at math and science. Hopefully, the CRC CD-ROM

and web site will provide insight into what engineers and scientists

actually do, and help students with their career decisions."

Our

customers will notice a self addressed stamped feedback card enclosed

in many of our reports, especially to newer customers. The card contains

9 simple questions for you to evaluate our performance. We want to

know what you think of your experience working with us. We are not

the biggest in our field, but we are striving to be the best. Our

goal is complete customer satisfaction, and the feedback cards are

one way to help us get there. Our

customers will notice a self addressed stamped feedback card enclosed

in many of our reports, especially to newer customers. The card contains

9 simple questions for you to evaluate our performance. We want to

know what you think of your experience working with us. We are not

the biggest in our field, but we are striving to be the best. Our

goal is complete customer satisfaction, and the feedback cards are

one way to help us get there.

One

of the questions asks if you would like to meet with MEi engineers

to discuss other materials and processing issues. We know that nothing

can replace the meeting across the table to better understand your

needs and our capabilities. We have many customers whom we meet with

routinely as part of our projects with them, and we know that this

has been a very effective tool. However, we know that this is not

always possible, especially for many of our customers from coast to

coast. Our goal this year is to visit more of you, our customers at

your facility. And as always, you are always welcome to come to Virgil. One

of the questions asks if you would like to meet with MEi engineers

to discuss other materials and processing issues. We know that nothing

can replace the meeting across the table to better understand your

needs and our capabilities. We have many customers whom we meet with

routinely as part of our projects with them, and we know that this

has been a very effective tool. However, we know that this is not

always possible, especially for many of our customers from coast to

coast. Our goal this year is to visit more of you, our customers at

your facility. And as always, you are always welcome to come to Virgil.

In

case you've ever wondered why ignorance rises to the executive level,

here is a simple explanation that is also mathematical proof: In

case you've ever wondered why ignorance rises to the executive level,

here is a simple explanation that is also mathematical proof:

Knowledge is Power. Time is Money.

And, as every engineer knows: Power=Work/Time

If Knowledge=Power and Time=Money, then

Knowledge=Work/Money

Solving for Money, we get

Money=Work/Knowledge

Thus, Money approaches infinity as Knowledge approaches zero, regardless

of the work done. What this means is: The less you know, the more

you make!

Dear Ann Landers:

The warning from "Careful in Colombia, MD.," to disconnect

microwaves when not in use applies to other small appliances as

well. Please print this letter. I wish I had seen one like it. Dear Ann Landers:

The warning from "Careful in Colombia, MD.," to disconnect

microwaves when not in use applies to other small appliances as

well. Please print this letter. I wish I had seen one like it.

One afternoon

when no one was home, my house sustained $42,000 worth of damage

from a fire started by a defective toaster oven. The oven, which

was only 3 years old, was not in use but was plugged in. The insurance

company that paid the cost of rebuilding the house brought a claim

against the toaster oven's manufacturer and was eventually reimbursed

for the loss. One afternoon

when no one was home, my house sustained $42,000 worth of damage

from a fire started by a defective toaster oven. The oven, which

was only 3 years old, was not in use but was plugged in. The insurance

company that paid the cost of rebuilding the house brought a claim

against the toaster oven's manufacturer and was eventually reimbursed

for the loss.

Please tell your

readers to be cautious with appliances and unplug them when not

in use.- Concerned in Capitola, Calif. Please tell your

readers to be cautious with appliances and unplug them when not

in use.- Concerned in Capitola, Calif.

All of us take

the safety of our kitchen appliances for granted. After all, they

are UL listed and are manufactured by companies whose brand names

are household words. However, failures do happen...and the consequences

can be severe. If the appliance is a heating device, such as a coffee

maker, toaster, toaster oven or breadmaker, a failure in the control

circuitry could cause the appliance to fail in the maximum heat

on condition, with disastrous results. MEi has conducted analysis

in similar cases where small appliance have caused fires with extensive

damage to property. So if you don't want us investigating a fire

at your home, follow the advice of "Concerned in Capitola,

Calif.," and unplug those small appliances when not in use.

If you won't do it when not in use, at a minimum unplug them when

you are on vacation or away from your home for more than a day. All of us take

the safety of our kitchen appliances for granted. After all, they

are UL listed and are manufactured by companies whose brand names

are household words. However, failures do happen...and the consequences

can be severe. If the appliance is a heating device, such as a coffee

maker, toaster, toaster oven or breadmaker, a failure in the control

circuitry could cause the appliance to fail in the maximum heat

on condition, with disastrous results. MEi has conducted analysis

in similar cases where small appliance have caused fires with extensive

damage to property. So if you don't want us investigating a fire

at your home, follow the advice of "Concerned in Capitola,

Calif.," and unplug those small appliances when not in use.

If you won't do it when not in use, at a minimum unplug them when

you are on vacation or away from your home for more than a day.

The scanning

electron microscope (SEM) is a powerful tool, capable of magnifications

up to 180,000 times. It allows us to reveal information which is

critical to metallurgical investigations, such as fracture modes

and surface characteristics. The scanning

electron microscope (SEM) is a powerful tool, capable of magnifications

up to 180,000 times. It allows us to reveal information which is

critical to metallurgical investigations, such as fracture modes

and surface characteristics.

The SEM can also

be fun to play with, because it allows one to view the surface of

anything at high magnification with great depth of field. All of

us have been amazed by the pictures of various insect parts, especially

the eye of a fly. The SEM can also

be fun to play with, because it allows one to view the surface of

anything at high magnification with great depth of field. All of

us have been amazed by the pictures of various insect parts, especially

the eye of a fly.

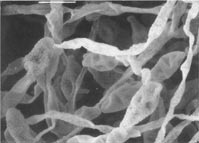

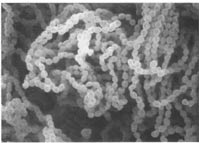

In our contest,

we take a look at an object on the SEM that should be familiar to

all of you. In this issue our photographs show something that might

be found in your kitchen, but you really wouldn't want to eat it.

The photographs are two different types of the same thing. Good

Luck. In our contest,

we take a look at an object on the SEM that should be familiar to

all of you. In this issue our photographs show something that might

be found in your kitchen, but you really wouldn't want to eat it.

The photographs are two different types of the same thing. Good

Luck.

1100X 1100X 1100X 1100X

Please fax, mail

or e-mail us (don't call) with your answer. We will draw a winner

from all correct entries received by June 6. The correct answer

and the winner will be published in the next issue Of Materials

Interest. Please fax, mail

or e-mail us (don't call) with your answer. We will draw a winner

from all correct entries received by June 6. The correct answer

and the winner will be published in the next issue Of Materials

Interest.

The prize is

a $50 restaurant gift certificate, so put on your thinking caps. The prize is

a $50 restaurant gift certificate, so put on your thinking caps.

Results:

Last issue, we

had many correct entries, with many people having seen the photographs

published in magazines like Popular Science in the past. The photographs

show the surface of a compact disk. The pattern of "bumps and

flats" are the 0's and 1's of the digital code. Last issue, we

had many correct entries, with many people having seen the photographs

published in magazines like Popular Science in the past. The photographs

show the surface of a compact disk. The pattern of "bumps and

flats" are the 0's and 1's of the digital code.

Our winner, drawn

at random from the correct entries, was Tom Hansel of Pacific Bearing

in Rockford, Illinois. His efforts earned he and his wife a nice

dinner at JMK Nippon Japanese Restaurant in Rockford. Pacific Bearing

is the manufacturer of the Simplicity (TM) line of linear plane

bearings, considered as the finest made. They also carry numerous

other linear motion technology products. They sell direct to OEMs

and through distributors, and their products are available throughout

the world. You may have seen the Pacific Bearing adds in magazines

like Machine Design and Design News, and they had a big display

at the Design Engineering Show at McCormick Plaza in Chicago this

spring. Our winner, drawn

at random from the correct entries, was Tom Hansel of Pacific Bearing

in Rockford, Illinois. His efforts earned he and his wife a nice

dinner at JMK Nippon Japanese Restaurant in Rockford. Pacific Bearing

is the manufacturer of the Simplicity (TM) line of linear plane

bearings, considered as the finest made. They also carry numerous

other linear motion technology products. They sell direct to OEMs

and through distributors, and their products are available throughout

the world. You may have seen the Pacific Bearing adds in magazines

like Machine Design and Design News, and they had a big display

at the Design Engineering Show at McCormick Plaza in Chicago this

spring.

Congratulations,

Tom. Congratulations,

Tom. |

Next:

1999 Fall Newsletter Next:

1999 Fall Newsletter |

|

|

|

|

|